Description

Material: Stainless steel

Grade: 201, 304, 316

Standards: ASTM A240 / A 240M, ASME SA – 240 / SA-240M , EN 10088.

Finishes: Mill Finish

Applications:

- Automotive industries

- Engineering and construction

- Pharmerceuticals

PRODUCT DESCRIPTION:

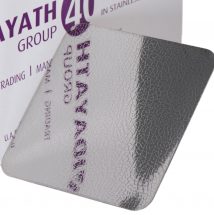

As the names suggests mill finish refers to the finish which mills input the least number of processes to produce coils or plates. This manufacturing method is a hot rolled process which results after melting stainless steel scrap into billets which are then passed through a series of compression rollers to flatten to the desired thickness.

After flattening the billet, they are rolled into coils which are then passed through an annealing furnace to release internal stresses and then passed through chemicals to pickle and passivate the stainless steel to restore corrosion resistance properties. The resulting finish is a rough and matte finish which is referred to as a mill finish or 1D finish.

Refer to the illustrative diagram below for the production of Mill finish materials.

Applications:

It can be polished if required but will not result in finish equivalent to material processed from 2B or BA.

Used in automotive industries for exhaust systems

Used in Road Transport for Road tankers, ship containers, chemical tankers and refuse vehicles

In engineering works as re-enforcement bars, Structural sections etc.

Technical Specification

| THICKNESS | WIDTH | MAX. LENGTH |

| 3MM – 50MM | 1M – 2M | 6M |

Reviews

There are no reviews yet.