Description

Material: Stainless steel

Grade: 201, 304, 316

Standards: ASTM A240 / A 240M, ASME SA – 240 / SA-240M, EN 10088

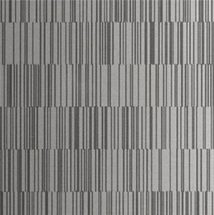

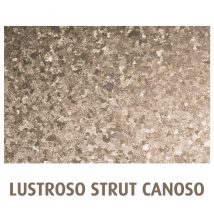

Finishes: Mirror Finish, smooth, shiny & reflective

Applications:

- Kitchen equipment

- Architectural- cladding and interior decorations

- Facades

PRODUCT DESCRIPTION:

Mirror Finish – Also known as a #8 finish. This finish is produced by polishing with at least a 320 grit belt or wheel finish. Care will be taken in making sure all surface defects are removed. The part is *sisal buffed and then color buffed to achieve a mirror finish. The quality of this finish is dependent on the quality of the metal being polished. Some alloys of steel and aluminum cannot be brought to a mirror finish. Castings that have slag or pits will also be difficult, if not impossible, to polish to a #8. Apply polishing compound sparingly to the face of a revolving buffing wheel. Repeat application of compound as needed during the buffing and polishing operations. Use only slight pressure in applying the revolving buff to the work surface, thereby allowing the buffing wheel and the polishing compound to do the work.

Advantages – shatter proof mirror panels can be achieved. Corrosion resistance is improved since the surface is quite smooth, limiting the opportunity for contaminants to react with the materials.

Disadvantages – typical processing leaves a degree of visible buff lines in the surface.

MIRROR FINISH THICKNESSWIDTH LENGTH0.5 – 20MM 1.2m. 1.5m6M

Reviews

There are no reviews yet.